Week 8

Mold Me Like One of Your French Girls: CNC Milling, Molding and Casting

Topics Covered:

- How To

- CNC Milling

- Molding and Casting

- Explorations

- CNC: Knut's Knife

- Molding and Casting: Bulbasaur

- Molding and Casting: Shotglasses

- Future: CNC Shelf

The assignment:

- Design something and make it using CNC. You may use the ShopBot (2D outlines), the Shaper (2D outlines) or the SRM-20 (2.5D molds).

- Create something by molding and casting.

0. CNC Practice:

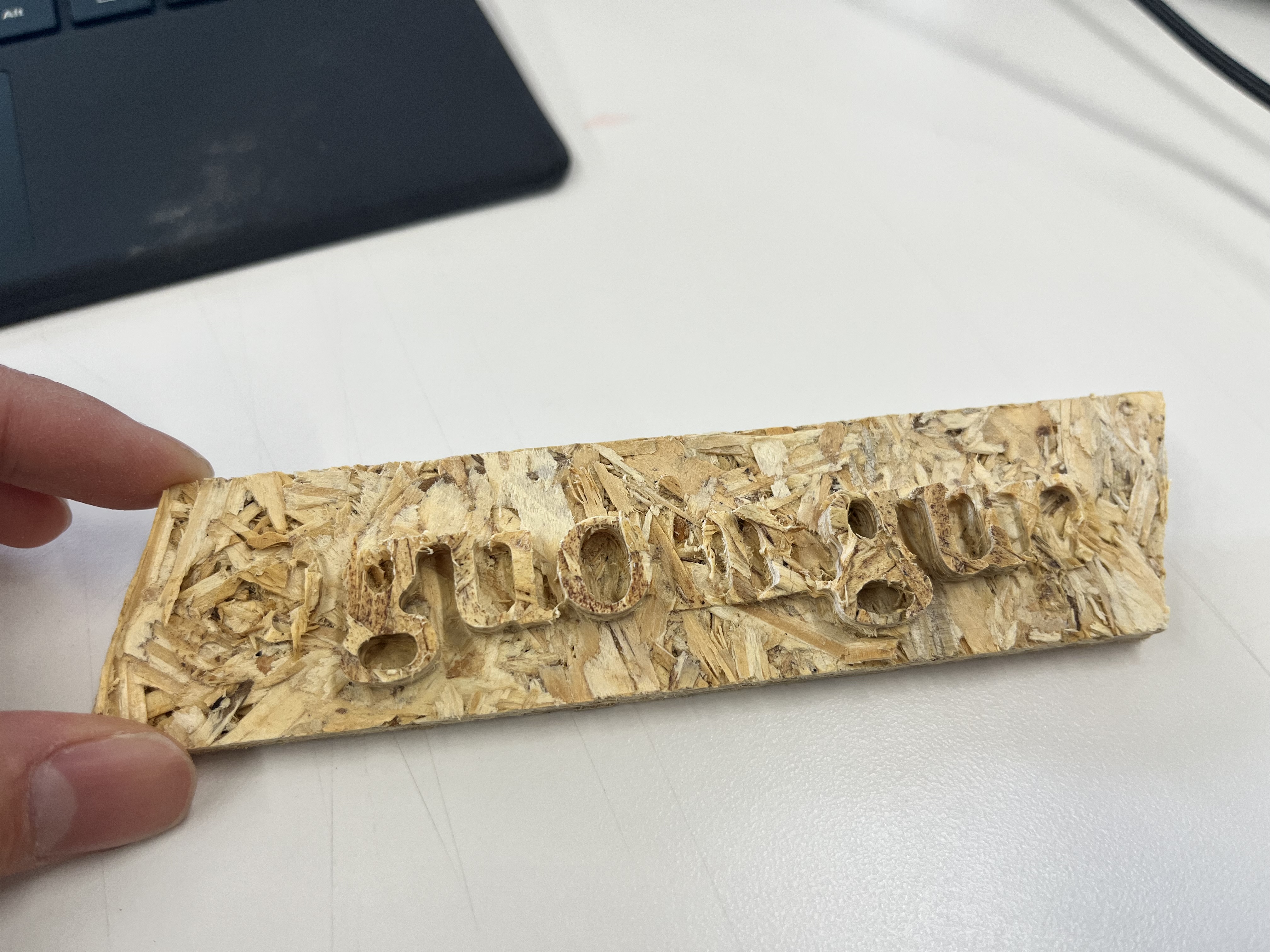

As part of our practice using the machine, I made my general social media handle @guoingup (IG, Snapchat) on Aspire.

I had originally intended for the letters to be cut deeper, but it came out like this which I actually loved (and helped inspire my project).

As part of our practice using the machine, I made my general social media handle @guoingup (IG, Snapchat) on Aspire.

I had originally intended for the letters to be cut deeper, but it came out like this which I actually loved (and helped inspire my project).

You might notice that the "@", "in", and "p" got cut off. 2 notes:

- This is oriented strand board (OSB), which I think looks cool, but might be prone to breaking off in small chunks since that's how it's literally structured.

- The CNC machine's end mill is only so big, maybe 1/8 inch here, so small cuts are a lot to ask.

1. Design and Make Something with CNC: Knut's Knife

For my CNC creation, I wanted to make a knife for my friend Knut.

The context:

The design:

One DXF file later...

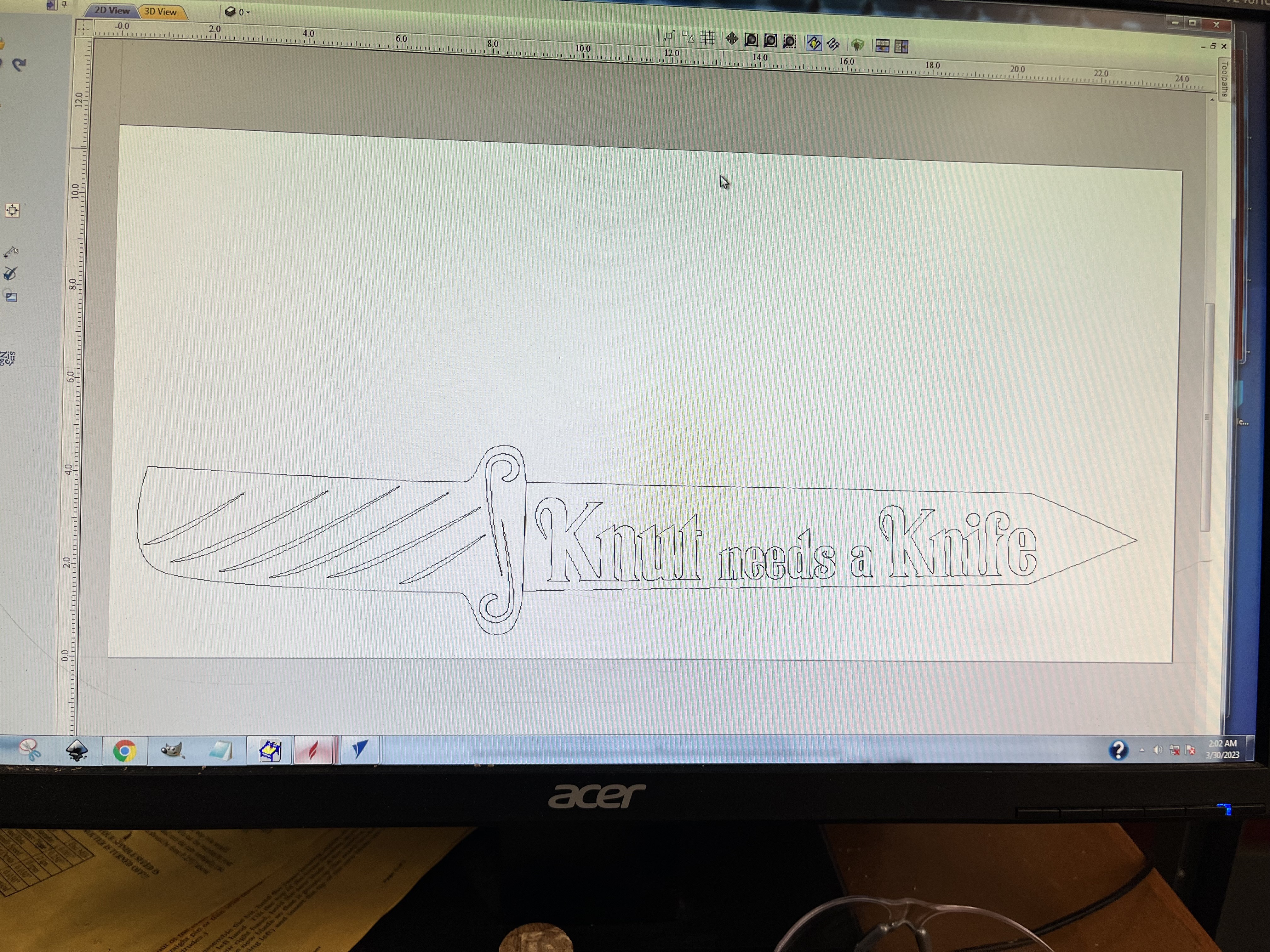

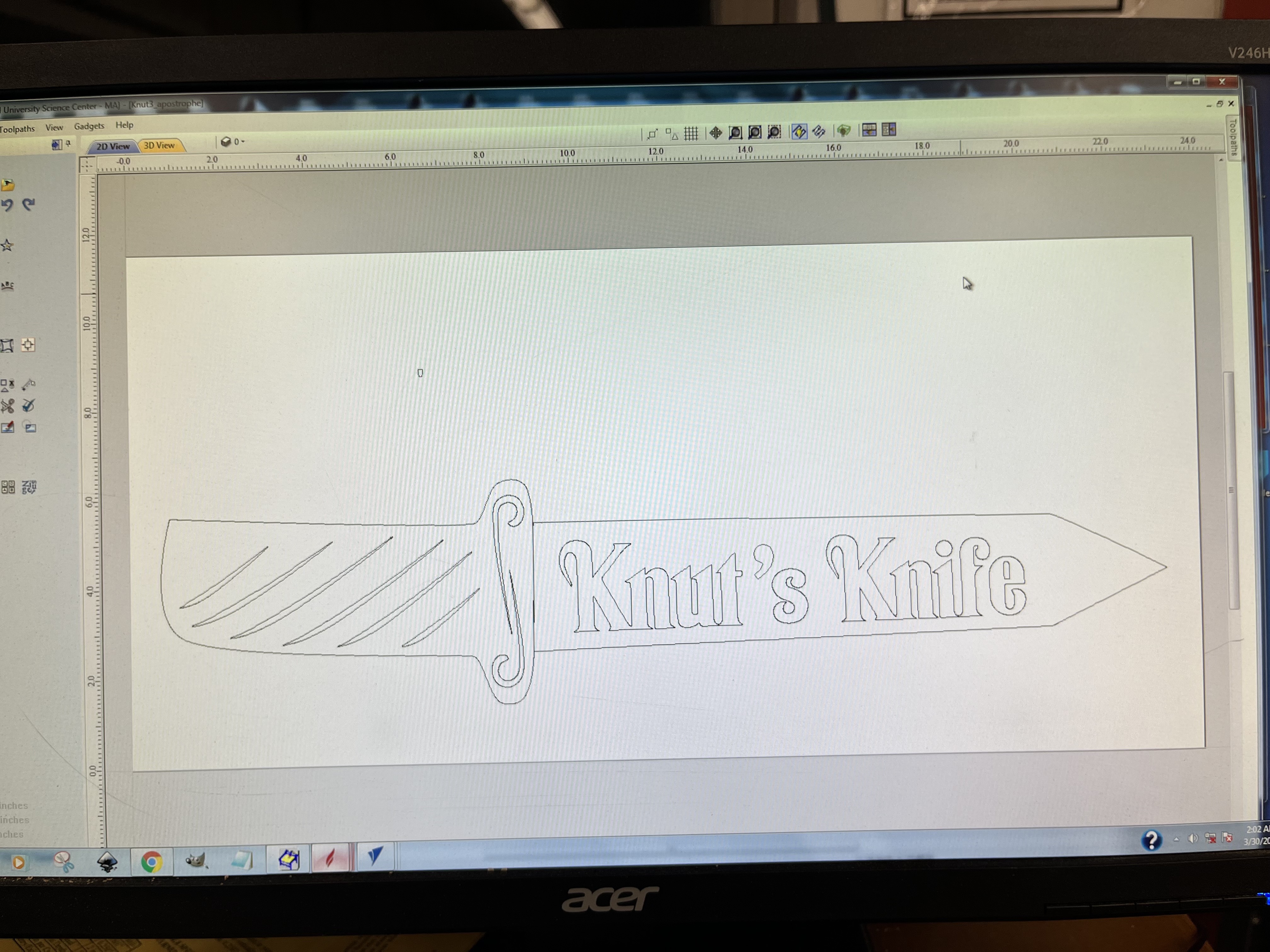

In Aspire:

It seemed that there were still too many fine details for our 1/8th inch end mill to handle, so I had to keep making the knife bigger and bigger until the program would allow me to make the necessary toolpaths. I used the pocket toolpath to flatten around the words for the blade, and the bevel toolpath to create interesting texture for the details on the handle.

I found Aspire surprisingly intuitive with all the tools I needed to finish the design on.

Since the ShopBot and the 1/8th inch drill was unable to get the finer details, I drilled the holes for the "s" and the "e" myself with the drill press:

And voila!

The context:

- His friend's dad asked him over dinner once if "Ka-nut wanted a ka-nife", which I just found hilarious.

- Knut's favorite movie is Knives Out.

The design:

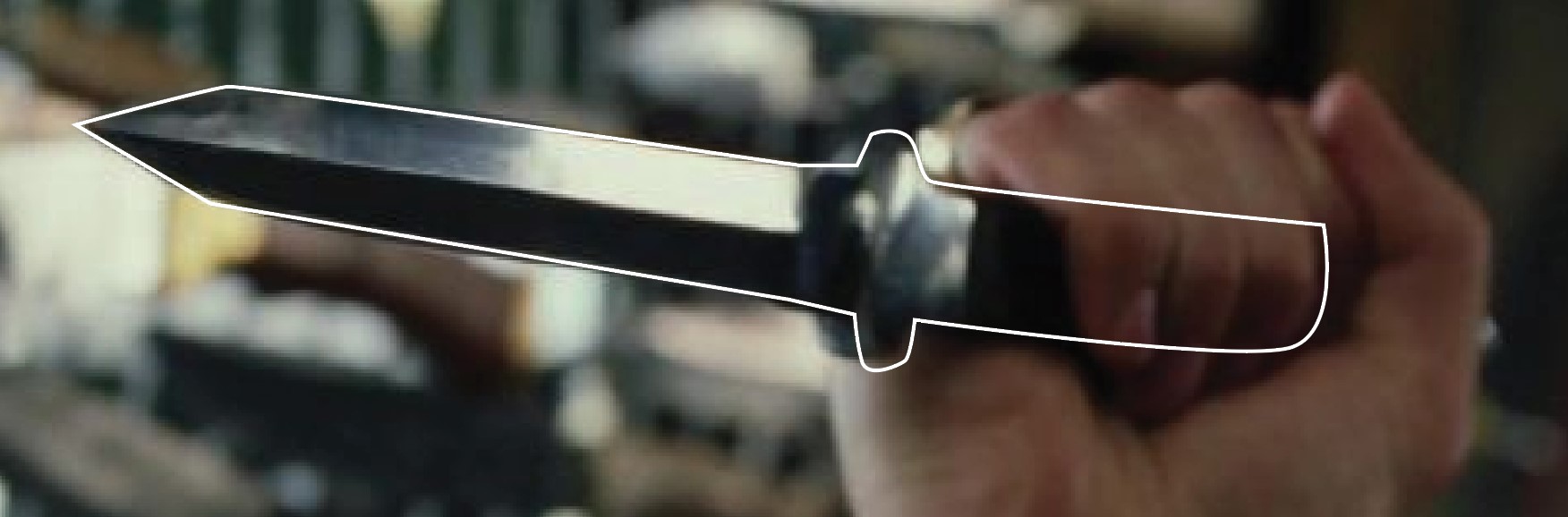

- I outlined the knife used near the end of the movie hehe:

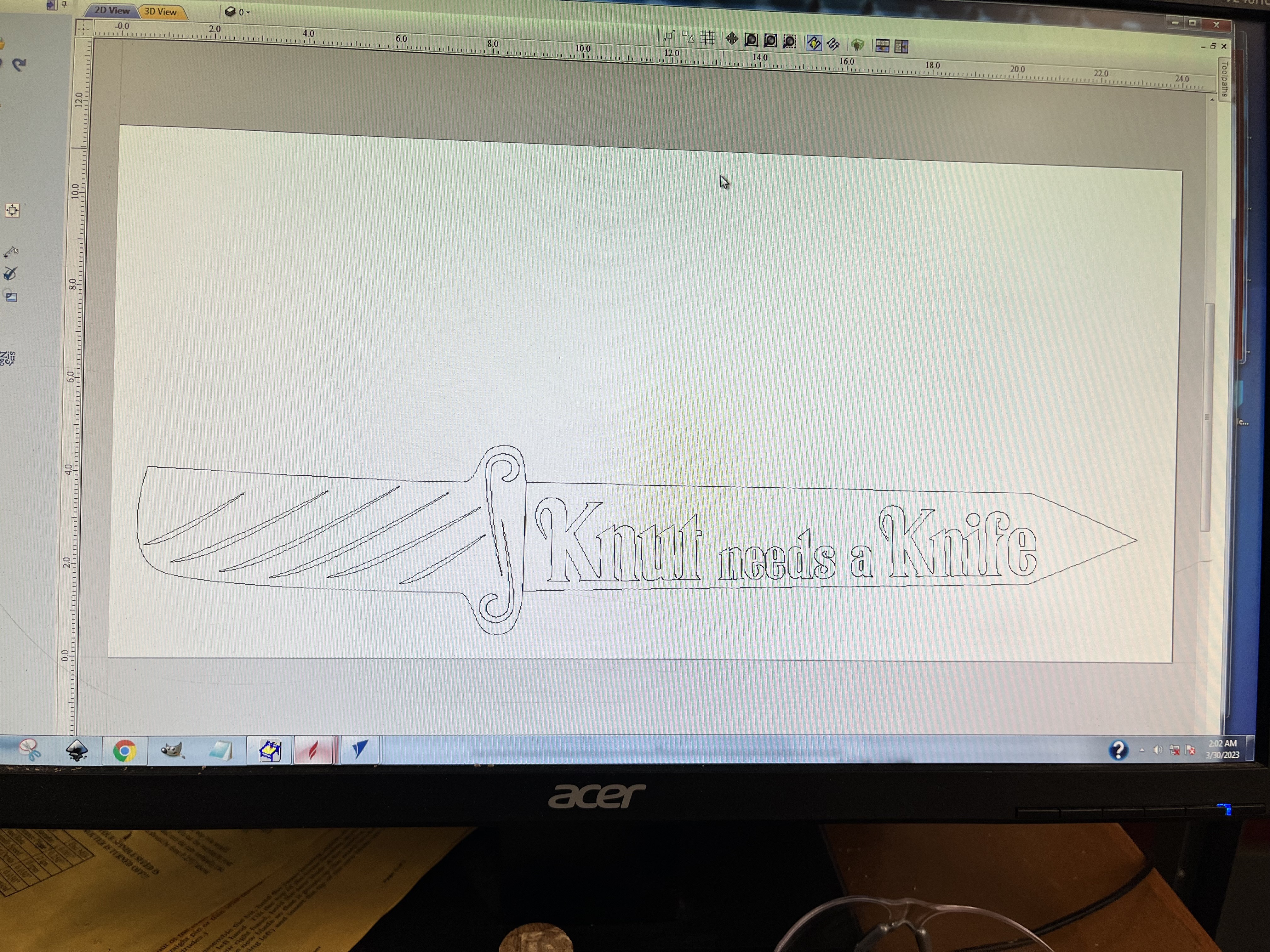

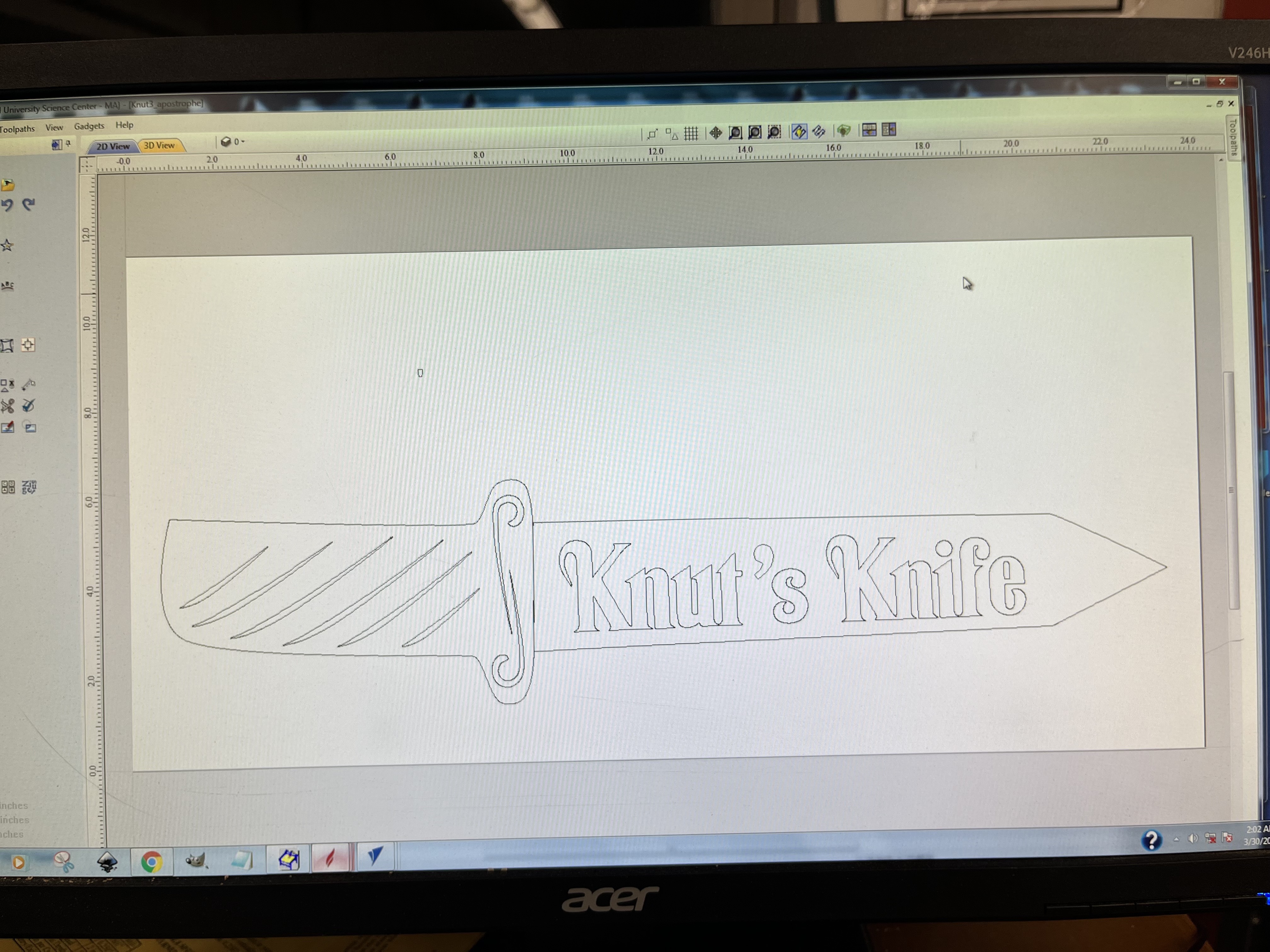

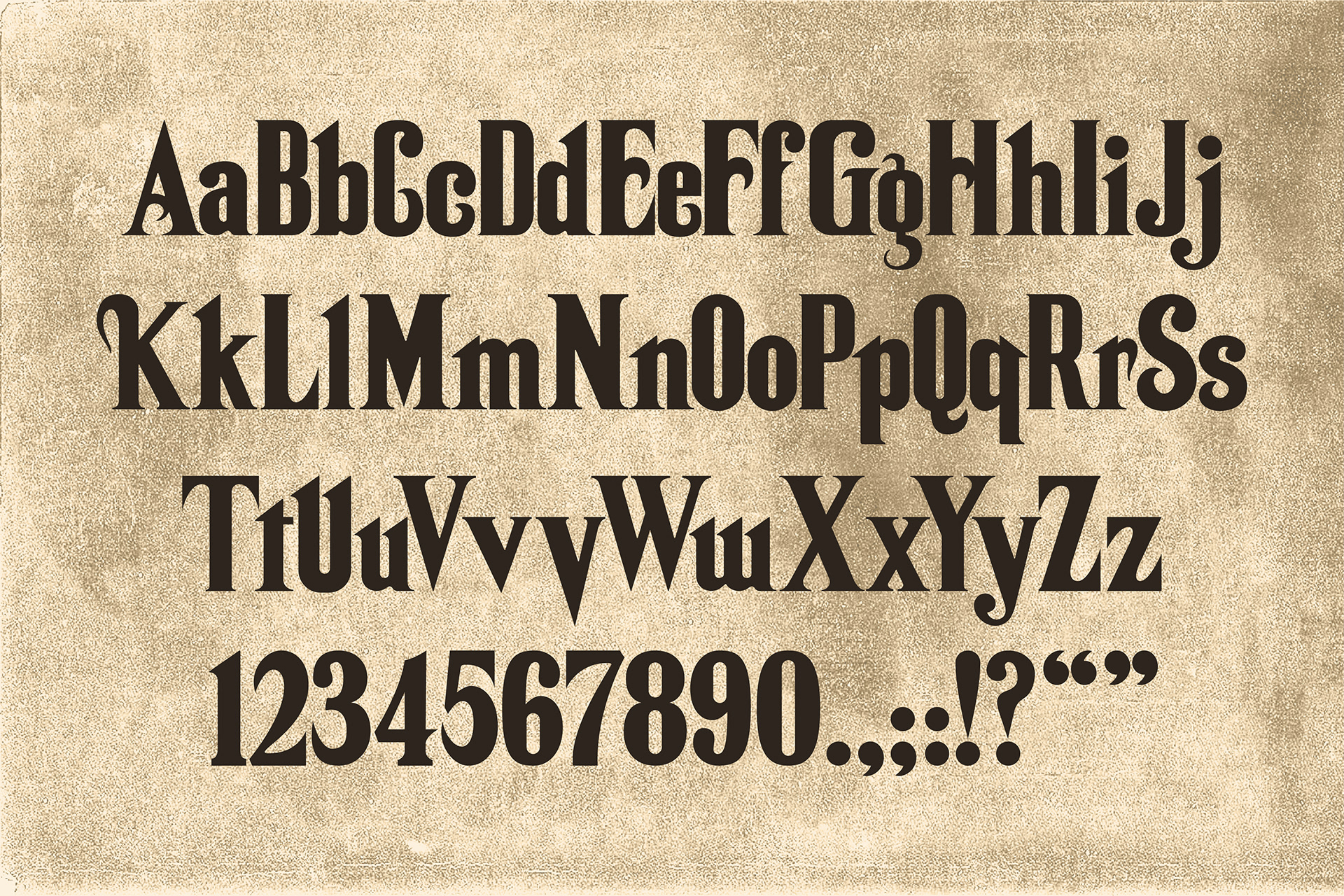

- And I wanted the blade to say "Knut needs a Knife" -- but in the typeface of Knives Out's title card:

- Here's the Knives Out title card:

-

I used the title card + a picture of Nic Dennis's Agatha Font + Adobe Illustrator's handy-dandy image trace feature:

Agatha Font:

Initial designs:

And here's my first knife design:

- Here's the Knives Out title card:

- I added some custom detailing to the handle, including spirals.

One DXF file later...

In Aspire:

It seemed that there were still too many fine details for our 1/8th inch end mill to handle, so I had to keep making the knife bigger and bigger until the program would allow me to make the necessary toolpaths. I used the pocket toolpath to flatten around the words for the blade, and the bevel toolpath to create interesting texture for the details on the handle.

I found Aspire surprisingly intuitive with all the tools I needed to finish the design on.

Since the ShopBot and the 1/8th inch drill was unable to get the finer details, I drilled the holes for the "s" and the "e" myself with the drill press:

And voila!

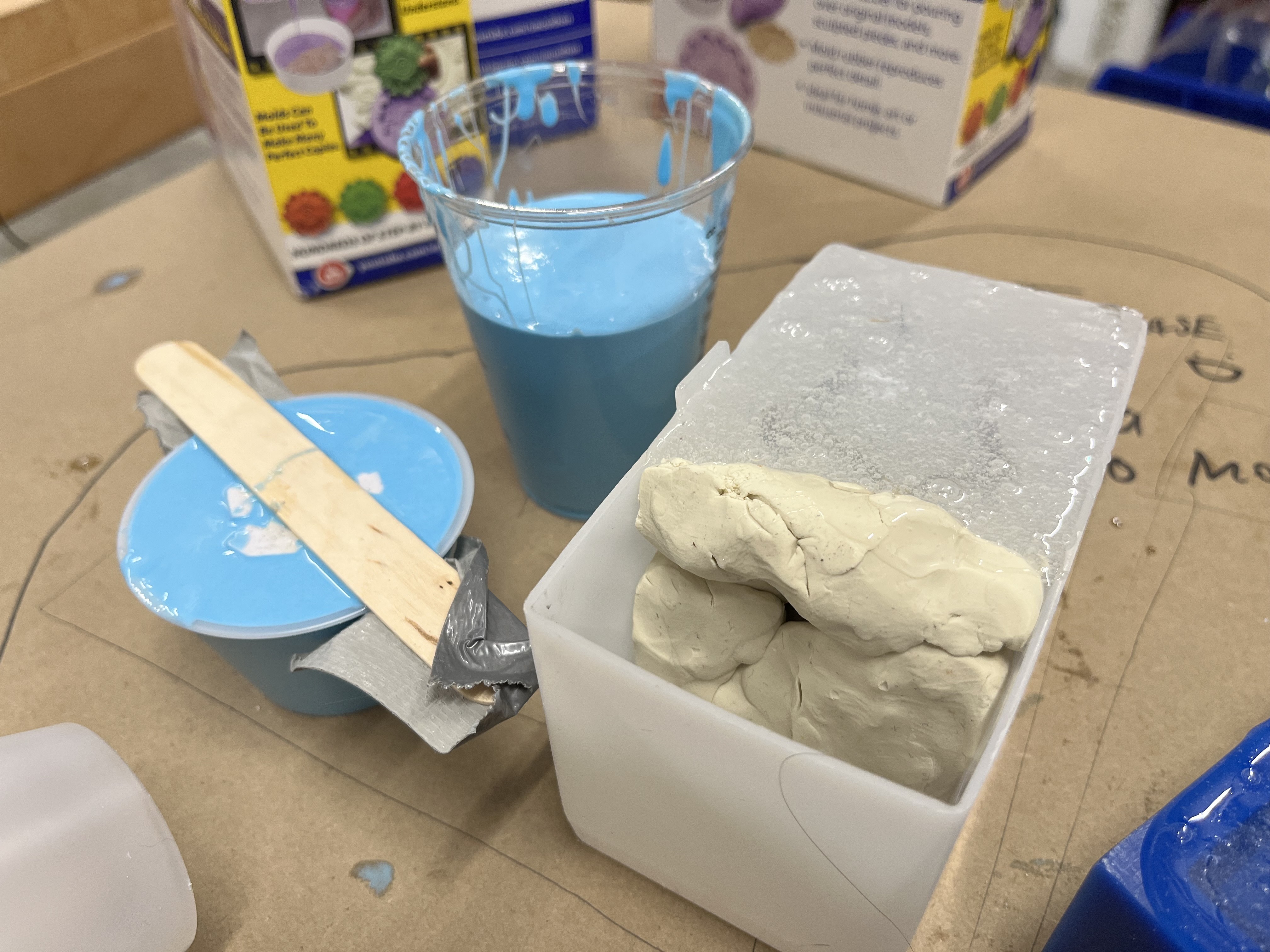

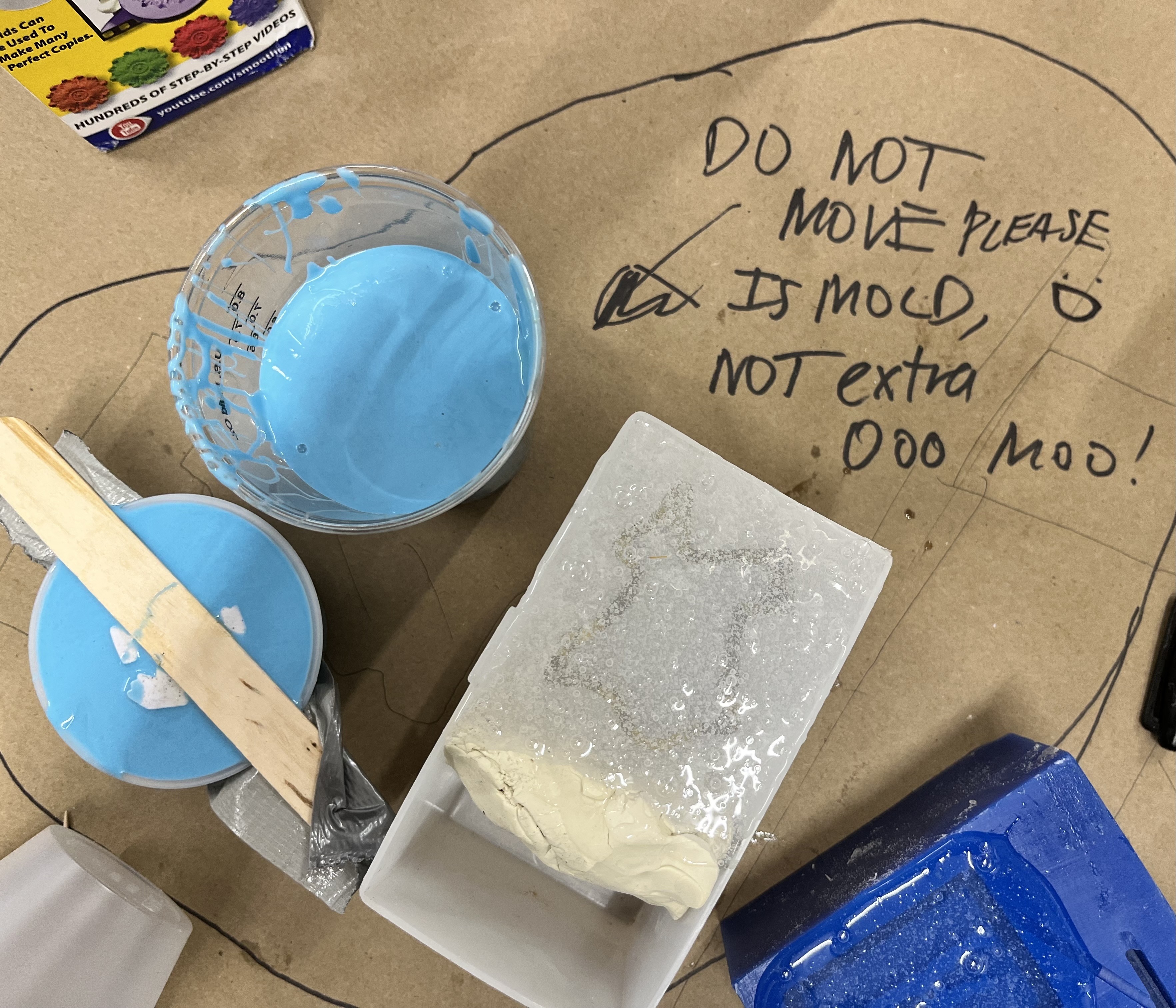

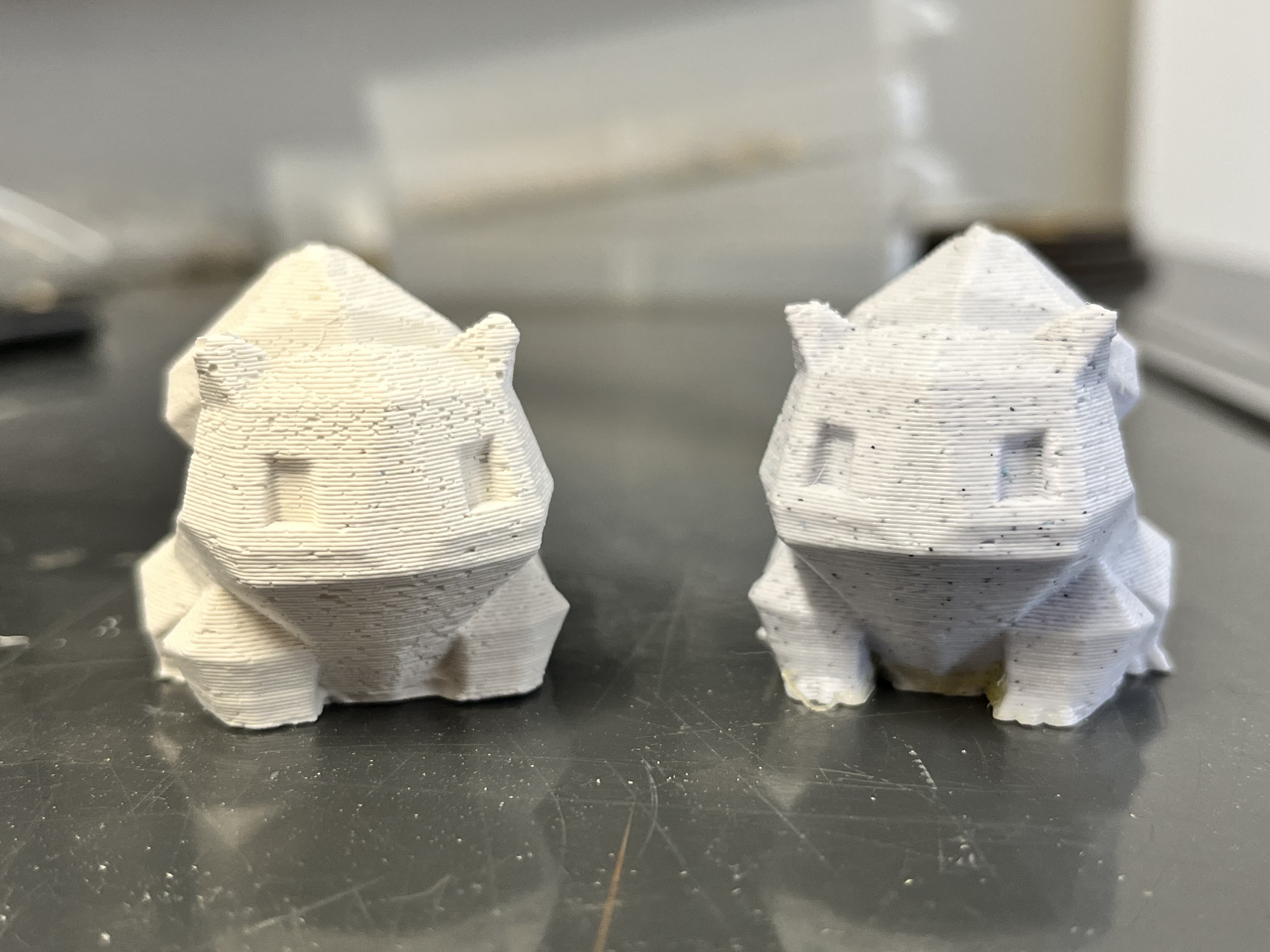

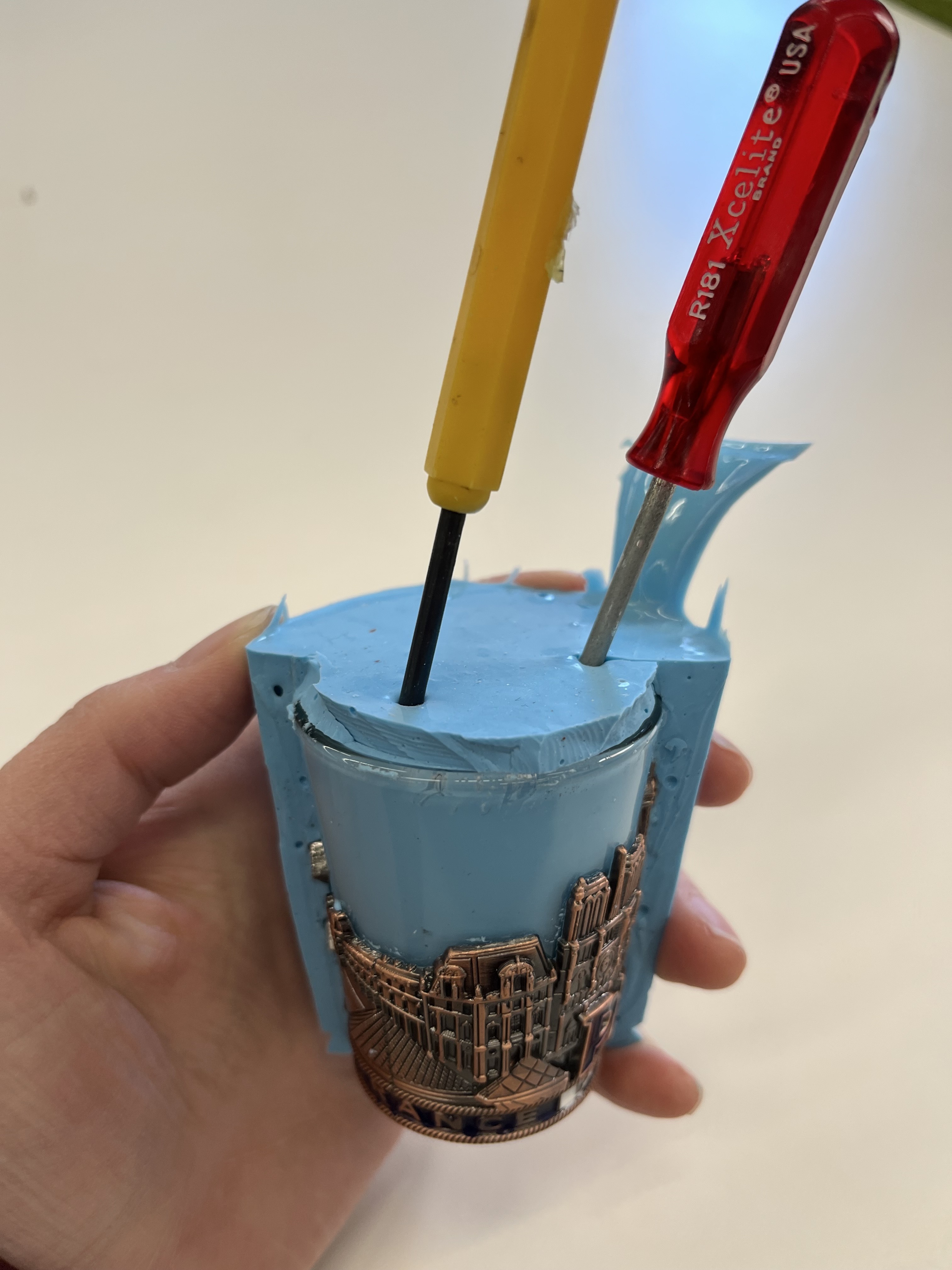

2. Molding and Casting: Bulbasaur + Shotglasses

My 3 Molds:

- Bulbasaur (the same 3D-printed Bulbasaur that Ted gave me

- Paris Shotglass

- Food-Grade Mold of my beloved Texas Shotglass

How Bulbasaur Came Out:

How the Paris Shotglass Came Out:

Need I say more?

How the Texas Shotglass Came Out: Easily, that's how. Although not pictured here, I was able to remove the Texas shotglass from the mold with relative ease, such that even the part of the mold that went inside the shotglass remained intact! (And not stuck inside the shotglass like with Paris. :/) I look forward to creating some chocolate Texas-shaped shotglasses!!!

When I went home, noticed some Oo Moo in my hair! :D It really gets everywhere.

Future Hope: Shelf/Table

I was hoping to make a tiny shelf table with the CNC Machine and OSB. Maybe I'll have time in future.